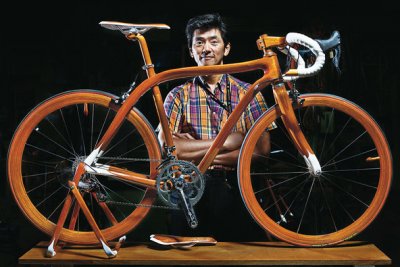

Sueshiro Sano, a ninth-generation shipwright, makes lightweight, bespoke wooden bicycles in his Tokyo workshop. His bikes, which take three months to assemble and can cost up to $20,000, use Honduras mahogany and are custom built for a 100-percent tailored fit. They’re also impossibly light — a result of Sano’s well-honed boat-building methods — and have become objects of worship, and in some cases, derision, for hipsters and bike experts everywhere. Case in point: at a handmade-bike convention in Denver earlier this year, several incredulous participants accused Sano of using carbon fiber in his designs. (He doesn’t.) But Sano, who built his first boat at 13 and subscribes to the Japanese principle of monozukuri (“making things”), shrugs off such accusations. “For me, it’s about pride,” he says.

Bovenstaande kreeg ik toegestuurd van mijn fietsvrienden uit Bangkok, leuk om hier te delen.

jaap