Hi All, I hope somebody can help me out in English.

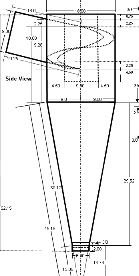

I have made myself a small dust collection system

for a portable Bosch table saw. The vacuum (small 1300W home vacuum) is connected

directly to the collection system and than from there I go to the table saw using a 3 meter

flexible pipe I bought a karwei which looks very similar to a normal vacuum pipe.

It all works great except that this pipe, makes a very loud noise like a wissel, it is so loud that I bearly hear the table saw.

Note: This is a little hobby and I don't need a big container

the pipe in the image was a test, now I have the same material but longer.

Do you think this because of the type of pipe I bought?

I have made myself a small dust collection system

for a portable Bosch table saw. The vacuum (small 1300W home vacuum) is connected

directly to the collection system and than from there I go to the table saw using a 3 meter

flexible pipe I bought a karwei which looks very similar to a normal vacuum pipe.

It all works great except that this pipe, makes a very loud noise like a wissel, it is so loud that I bearly hear the table saw.

Note: This is a little hobby and I don't need a big container

the pipe in the image was a test, now I have the same material but longer.

Do you think this because of the type of pipe I bought?